Trusted by

Demand Response Management (DRM)

In Australia, utilising demand response is an increasingly popular strategy for large energy consumers.

Adjusting your energy consumption to respond to periods of high or low electricity offers the opportunity to reduce electricity costs, unlock additional revenue, meet sustainability goals and help deliver grid stability.

One form of Demand Response is DRM where energy consumers can voluntarily reduce electricity consumption in exchange for energy bill savings. This can be done automatically with a range of mechanical and software options.

In the past, savings have mainly been in the form of demand (kVA) charge reductions, but now there can be incentives for consumption (kWh) reductions in some circumstances.

Some of the most popular approaches do not have a huge impact on operational performance, yet can prevent significant savings opportunities.

Embedded Electrical Networks

Sustainable Savings is experienced with the creation of embedded networks. This could be an apartment block or industrial estate with many meters, or it could be simply two meters on a commercial site that will benefit from converting them into one and simply use sub-meters for any use monitoring or billing.

Sustainable Savings is an AER-approved Embedded Network Manager. This means we can assist in managing a network once it is created. This includes:

- Coordinating the transition of new customers and the departure of existing customers

- Manage any queries from customers of the embedded network

- Ensure the embedded network complies with all AER requirements

- Represent the landlord/s or strata of the embedded network.

Check out our Rent-Your-Roof approach for a unique way of benefiting from embedded networks and solar, without any costs.

LED Lights And More

Sustainable Savings is experienced with a range of lighting solutions. Many sites have already upgraded to LED lights, however, there can be other savings opportunities with sensors and timers.

More than opportunities to enjoy savings, there are many situations where lights generate a number of additional benefits including safety, space/environmental mood or even enhancing a feature within a defined space.

Power Factor Correction (PFC)

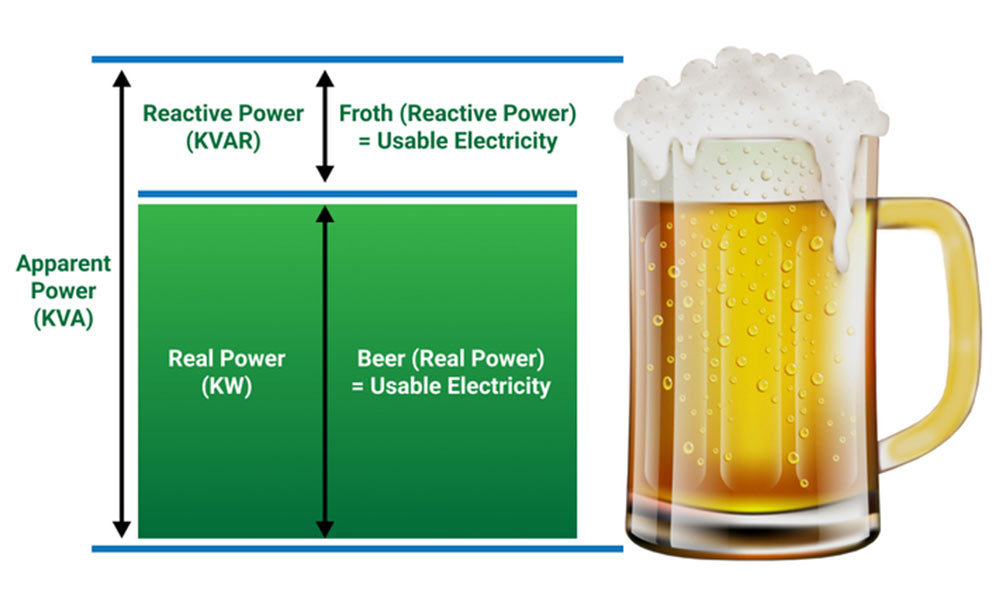

Power Factor assesses the efficiency of your site’s electricity usage. Simply put, it’s the comparison between the actual power your business uses (also known as real power) and the total power supplied from the grid (often referred to as apparent power).

Electricity network providers are now billing businesses for both their energy consumption and the demand they place on the grid. If your energy bill includes a kVA (kilo-volt-ampere) charge, then the Power Factor significantly affects your electricity costs.

Power Factor, ranging from zero to one, indicates how efficiently your business uses electricity. A value close to one signifies efficient usage, termed as a “good Power Factor,” implying your equipment is operating effectively. Conversely, a lower Power Factor indicates inefficiency, leading to potentially higher network tariff charges due to excess energy use.

PFC Units Functionality

PFC (Power Factor Correction) units optimise power delivery to your business using software-controlled capacitors. These capacitors function similarly to batteries, injecting the right amount of power to even out your energy demand throughout the day. They come in various sizes to meet your specific needs. Speak to a member of the Sustainable Savings team to learn more.

Benefits of PFC Units

- Reduced Energy Costs: By improving the Power Factor, these units can lower kVA demand charges and improve your financial savings.

- Extended Equipment Life: Enhanced Power Factor means better voltage for electrical equipment, prolonging machinery lifespan and efficiency.

- Lower Emissions: A better Power Factor decreases the supply of non-useful or reactive power, aiding in reducing your carbon footprint.

Causes Of Low Power Factor

Low Power Factor is often a result of inductive loads, typically found in commercial and industrial sites. Common sources include:

- Electric motors, transformers, and coils

- Industrial fans in heating and cooling systems

- Compressors and relays in refrigerators

- Ventilation units

While reactive power is necessary for powering these induction machines and cannot be fully eliminated, it can be effectively managed with capacitors like those in Power Factor correction units.

Voltage Optimisation (VO)

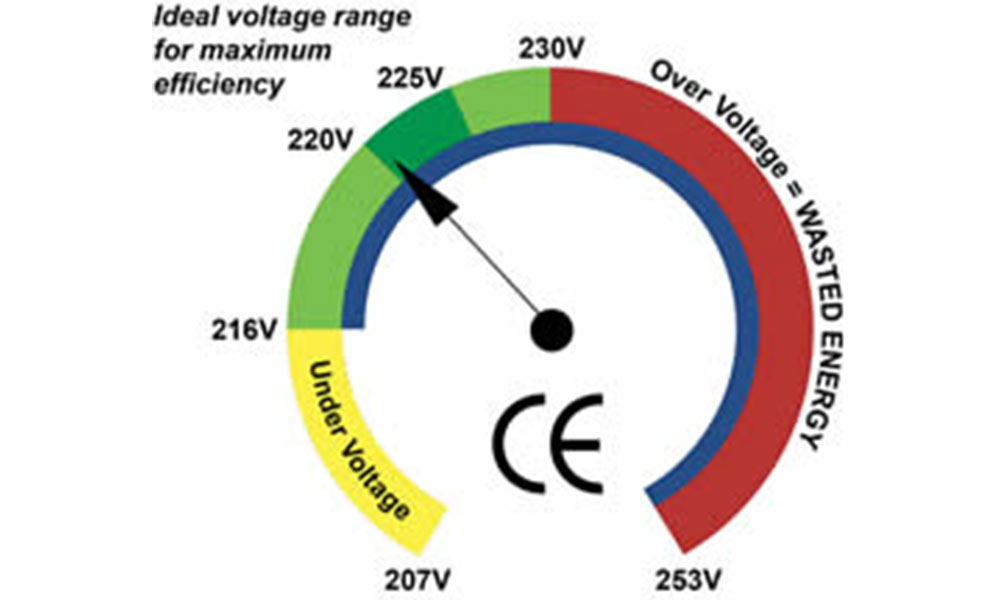

Voltage optimisation is an effective method for managing and reducing the power supply from the National Grid. This technique adjusts the supplied voltage to its most efficient level, helping you use less electricity and simultaneously decrease your carbon emissions.

This technology works by adjusting supply voltages to the lower end of the legal voltage spectrum. As a result, it can typically lead to energy savings of about 5%, and sometimes even up to 10%. Notably, the higher the voltage, the greater the power consumption, especially in cases of pure resistance loads.

Advantages Of Voltage Optimisation

- Effectively streamlines power usage, leading to reduced electricity costs and a smaller carbon footprint.

- Potential for return on investment within 3-5 years, depending on voltage supply.

- A proven method with over 100 years of use, ensuring only optimal voltage levels are supplied to the equipment.

- Flexible installation options, either at the distribution level or directly at the low-voltage incoming line.

Drawbacks Of Voltage Optimisation

- Initial costs can be substantial.

- Installation may cause temporary disruptions in the power supply.

- Sites with lower voltage supplies may not see significant benefits from voltage optimisation.